The MI Honors 2024 Women MAKE Award Winners

The Manufacturing Institute—the NAM’s 501(c)(3) workforce development and education affiliate—had ample reason to celebrate last night.

What went on: The MI held the 2024 Women MAKE Awards gala, a night that recognizes outstanding women in manufacturing. Each year, the awards pay special tribute to 100 peer-nominated women leaders (“Honorees”) and 30 rising female stars (“Emerging Leaders,” women under the age of 30) in the industry.

- The event, held this year at The Anthem—a waterfront concert venue in Washington, D.C.—was sponsored by Caterpillar, Toyota, BASF, Trane Technologies, International Paper, Johnson & Johnson, Novelis and others.

- It featured a vocal performance by singer Loren Allred, platinum-selling singer-songwriter of “Never Enough” from “The Greatest Showman” musical, who gained widespread fame after appearing on “Britain’s Got Talent” in 2022.

What was said: Caterpillar Group President of Resource Industries, NAM Executive Committee Member and Women MAKE Awards Chair Denise Johnson told the night’s award winners that she’s been “the only woman in a room, or the only woman on a project” many times in her career.

- But “[l]ooking around this theater and seeing the faces of the Honorees and Emerging Leaders tells me that times are changing.”

- She then addressed the honorees directly, saying, “Your success, your work ethic and your stories will inspire the next generation of manufacturing leaders. … You are moving us along toward a future when women are not underrepresented in our industry.”

From Honoree to Vice Chair: Toyota Motor North America Senior Vice President, Electric Vehicle Supply Susan Elkington—a 2014 Honoree of the awards, formerly called the STEP Ahead Awards—was this year’s awards vice chair. She attested to the power of the awards to help women advance in their careers.

- “[T]he Women MAKE network … helped me realize the many qualities and experiences uniting all the women who have been inducted into this amazing network.”

- She noted the cruciality of the MI’s Women MAKE initiative, which “provides a platform for role models and mentors to encourage women to enter the field and succeed in it.”

No limits: NAM President and CEO and MI Chairman of the Board Jay Timmons also discussed the importance of role models, a label aptly applied to all the award nominees.

- Timmons, a parent of three, told the audience that he and his children recently learned the story of 30-year-old Cole Brauer, who last month made history as the first American woman to sail solo nonstop around the world.

- Brauer’s story “sends a message to those—frankly, women or men—who might have been led to believe there were limits to what they could achieve or that their careers might be confined within guardrails,” he said. “Your examples are inspiring people in a similar way. You are powerhouses—your dynamism, your drive, your enthusiasm—all these qualities supercharge modern manufacturing, making our industry an even more powerful force for good.”

“Amazing things”: MI President and Executive Director Carolyn Lee called the nominated women “powerhouses who have accomplished amazing things.”

- “You deserve this recognition for your excellence and for everything you do to uplift others,” Lee told the award nominees. “But we’re not just celebrating. Being here to recognize these winners is shining a light and fueling the work to close the gender and talent gap in manufacturing.”

- Women account for less than one-third of the American manufacturing workforce, she went on, but endeavors such as the MI’s Women MAKE America initiative—the nation’s premier program dedicated to closing the gender gap in the sector—“and companies like yours are committed to closing that gap.”

Learn more: For a full list of this year’s award winners, click here.

From Mentee to Mentor: Rockwell Automation’s Aaliyah Brown

To hear Aaliyah Brown tell it, the start of her career in manufacturing was the result of a happy accident.

“My interest in manufacturing actually started accidentally,” the Rockwell Automation quality engineering team lead said with a laugh. “I was hired as a high school intern [at age 16]. I had a lot of different positions within my role, from [learning] how our different products are utilized in the field, to project management, to printed circuit board design. That’s when I really started to dip my toe into manufacturing.”

A quick ascent: After obtaining her bachelor’s degree in electronic engineering technology from Cleveland State University in 2019, Brown—who works at Rockwell Automation’s Twinsburg, Ohio, location—was hired full time by the automation and digital transformation technologies company as a process engineer.

- Three years later, she was made a quality engineer. Just a year after that, she was promoted to quality team lead.

- Her meteoric rise is one of the reasons her colleagues nominated her for this year’s Women MAKE Awards, honors given annually by the Manufacturing Institute, the NAM’s 501(c)(3) workforce development and education affiliate, to women in manufacturing who have accomplished remarkable successes at their companies.

The elevator speech: Her day-to-day job may be complex, but for the layperson, Brown can break down her duties in just a few sentences.

- “Manufacturing quality can be explained as anything that goes wrong within a manufacturing facility,” she said. “My team has to figure out why it happened and how to fix it to make sure it does not happen again.”

Paying it forward: Brown credits a great deal of her early professional success to mentor and colleague Marzell Brown (“no relation whatsoever”), a talent management lead at Rockwell Automation.

- Like Brown, Marzell Brown is a graduate of the Cleveland Metropolitan School District. Years ago, seeing a lack of programs in the greater Cleveland area designed to expose youth from traditionally underrepresented communities to science, technology, engineering and math careers, he helped found Brown’s alma mater, Cleveland’s MC2 STEM High School. Later, he spearheaded the internship program at Rockwell Automation’s business engineering unit that Brown completed.

- “Before I started going to summer camp at a private school, I had no idea what an engineer was,” Brown continued. “No engineers were in my family at the time. I was in the second graduating class of MC2 and about, I think, the seventh cohort of students Marzell brought in.”

- Inspired by her own experiences, in 2017—while still in college—Brown founded the nonprofit Build Sessions CLE, a mentorship initiative for college-bound STEM students from underrepresented communities.

- “All of the wonderful things that Marzell did for me and others like me, all of those best practices, those are what I brought over” to my job and to Build Sessions CLE, she said.

Changing perceptions: Brown—who helps lead Rockwell Automation’s annual Manufacturing Day events—believes that if more young people knew what modern manufacturing was really like, they would be much more inclined to enter the field.

- “I want to reach back … into these high schools, to provide these students with the great opportunities [I had] and show them that, yes, you can be successful here, and manufacturing facilities aren’t dirty and dingy,” she said.

Calling all women: She knows, too, the importance of shoring up the percentage of women in manufacturing in the U.S., which is around 30%.

- And there’s encouraging news on that front from the Rockwell Automation internship program that launched Brown’s career: If current trends continue, the number of women coming into the company from that program is going to rise, she told us.

- “[To all the] young ladies who don’t know exactly what they want to do, but have interests—say, sewing or project management or just wanting to help people— there are ways to be able to use all of those” talents in manufacturing, Brown said. “And you can have a very lucrative career here.”

“Why Inclusion Matters”: GM’s Stephanie Thompson on STEM, Women in Manufacturing

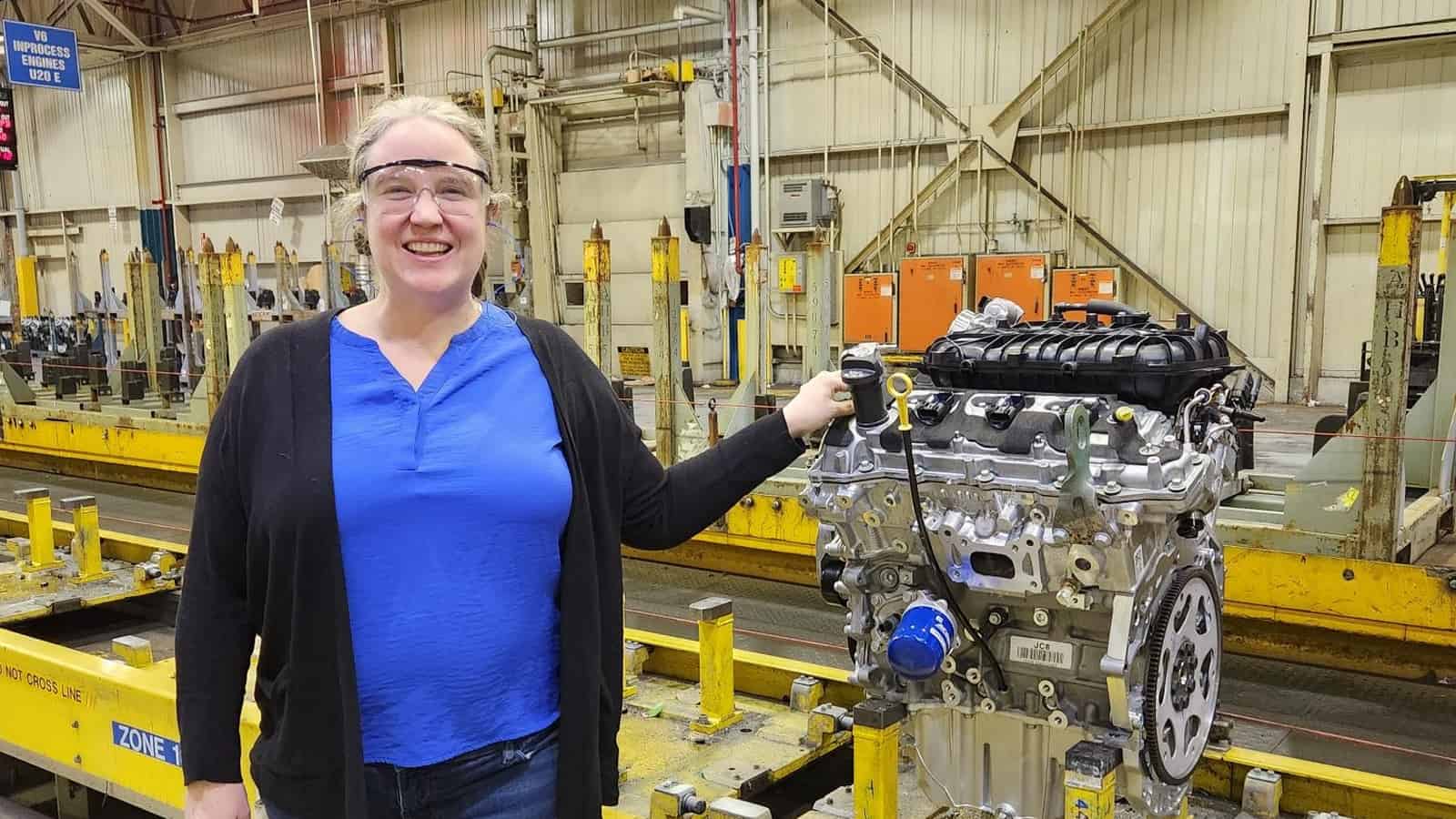

Stephanie Thompson may not have always intended to go into manufacturing, but she’s very glad she did.

The path taken: “You don’t necessarily plan your journey, but sometimes you can look back and see how those paths presented themselves,” and you’re thankful they did, said the engineering manager at General Motors’ facility just outside St. Catharines, Ontario, Canada.

- “My career in manufacturing started in internships in university. I worked for a food manufacturer, for a company that made above-ground swimming pools … It was a great chance to try out different businesses, and I [realized that I] love the buzz and excitement that manufacturing has.”

Award nominee: Thompson is a 2024 Honoree of the Women MAKE Awards, honors given annually to 130 women making a difference in manufacturing by the Manufacturing Institute, the NAM’s 501(c)3 workforce development and education affiliate.

- Thompson—who started working for GM full time right after university and has held multiple positions in her 23 years there—was the first woman to become an engineering manager in her time at her site.

- Women MAKE Award winners will be celebrated April 18 at the 2024 Women MAKE Awards Gala in Washington, D.C.

Always improving: An Ottawa native and graduate of the University of Waterloo, Thompson sums up her very complex job as “a manufacturing assembly specialist [who] makes sure people can do their jobs safely—and do it over and over again.”

- She oversees the assembly of whole powertrain lines. For one particular engine, “I was there for the first one made, and I was here for the last—we made over 5 million,” she said of a recently retired line.

- “We are always looking to make improvements, to make things more cost effective, to make things simpler,” she said. “The problem-solver part of me really enjoys making those incremental differences every day. [In manufacturing,] you get that sense of satisfaction from making stuff and ultimately giving a customer what they want.”

Women in STEM: Thompson, who has been recognized several times in her native Can

ada for her commitment to women’s education in science, technology, engineering and math, somehow found the time a few years ago to launch STEMbySteph.com, a STEM-focused website that includes a workshop series for women in the fields.

- She is also a mentor for FIRST Canada, which aims to interest kids in science and technology, and a regular speaker on related topics.

- “There are so many great women coming up through the ranks” in manufacturing today, she told us. “I want them to know there isn’t a limit to what they can do. I want to put myself out there as a technical role model, so women who apply [for manufacturing and STEM jobs] see themselves on the interview panel. They should know there’s a space for them in manufacturing.”

Work in progress: And while she’s had “nothing but great experiences with the men in manufacturing,” Thompson said the industry as a whole could benefit from “having some conversations” to make sure women feel welcome.

- “I don’t think it’s malicious,” she said, of the relatively low number of women in manufacturing (they make up about 30% of the

manufacturing workforce). “But one of the things you have to do as a leader is create intentionality and create environments where conflict is positive, where you can all create ideas to [fix] the problem and where individuals feel safe being themselves.”

Study: Manufacturing in U.S. Could Need Up to 3.8 Million Workers

The U.S. manufacturing industry could require some 3.8 million jobs to be filled within the next decade, according to a new joint study from the Manufacturing Institute, the NAM’s 501c3 workforce development and education affiliate, and Deloitte.

What’s going on: “Taking charge: Manufacturers support growth with active workforce strategies” found that manufacturing in the U.S. has emerged from the global pandemic on strong footing and is likely to continue to grow in the next few years.

- That growth will call for even more skilled workers—particularly statisticians, data scientists, logisticians, engineers, computer and information systems managers, software developers and industrial maintenance technicians—spotlighting the need to build the national talent pipeline.

- “Pandemic-driven shifts have already created hundreds of thousands of new jobs, and now we are seeing increased demand for digital skills that need to be met or risk further widening of the talent gap,” said Manufacturing Institute President and Executive Director Carolyn Lee.

Key findings: Top takeaways from the report include:

- If workforce challenges are not addressed, more than 1.9 million of the up to 3.8 million jobs likely to be needed between this year and 2033 could go unfilled.

- Some 65% of manufacturers polled said attracting and retaining talent is their primary business challenge.

- About 90% said they are forming at least one partnership to better attract and retain employees, and on average they have at least four such partnerships.

- Approximately 47% indicated that apprenticeships, work study programs or internships at manufacturing companies would be the most effective way of increasing interest in the industry.

- Some 47% also said flexible work arrangements—such as flex shifts, shift swapping and split shifts—have been their top retention tool.

The bottom line: Manufacturers continue to face a talent shortage—and the MI has the initiatives and resources ready today to help manufacturers address these challenges.

- From the recent flexibility white paper—which explains how manufacturers can build and deploy flexibility options for the 49% of workers that are on the production teams—to the high school internship toolkit that allows manufacturers to start a recruiting pipeline in high schools, to the FAME USA apprenticeship program training global best multi-skilled maintenance technicians and more, the MI has solutions to the hurdles highlighted in this study. Learn more at themanufacturinginstitute.org.

Skilled Trades See Interest Uptick

More young people are choosing skilled trade jobs after high school, The Wall Street Journal (subscription) reports.

What’s going on: “Enrollment in vocational training programs is surging as overall enrollment in community colleges and four-year institutions has fallen. The number of students enrolled in vocational-focused community colleges rose 16% last year to its highest level since the National Student Clearinghouse began tracking such data in 2018. The ranks of students studying construction trades rose 23% during that time, while those in programs covering HVAC and vehicle maintenance and repair increased 7%.”

Why it’s important: The trades, including manufacturing, have experienced a worker shortage in recent years as the older generation of employees retires.

- Finding and retaining quality talent is consistently a top business challenge among manufacturers, according to the NAM’s Manufacturers’ Outlook Survey, a quarterly polling of the industry.

- But now, trade-apprenticeship demand is surging, perhaps a signal that positions will start to fill.

Perception change: For many years the vocational education wing of one high school in Sheboygan, Wisconsin, was called “greaser hall,” but lately that’s started to change, a counselor there told the Journal.

- “[B]usinesses have raised funds and donated new equipment, including robotic arms … [and] those classrooms now sit at the building’s main entrance. ‘There’s still a presumption that four-year college is the gold standard, but it doesn’t take as much work to get people to buy into the viability of other options,’ [he said].”

The last word: Indeed, the Manufacturing Institute, the NAM’s 501(c)3 nonprofit workforce development and education affiliate, is seeing significant growth in its FAME initiative, an earn-while-you-learn training program with more than 40 chapters in 16 states—and more forming all the time. FAME, which was founded by Toyota and is now led by the MI, is truly the American model of skills training, according to MI President and Executive Director Carolyn Lee.

- “FAME is training thousands of global best technicians nationwide and the number of program participants is on the rise,” she said. “This is good news for manufacturing, which sorely needs talent to continue to make the many, many things people use every day.”

An Engineer Looks to the Future at ExxonMobil

It was an internship in modern manufacturing that changed Bobi Simonsen’s view of the industry—and gave her a sense of how many different kinds of opportunities were available.

“I remember school projects where I would just picture an engineer with a hard hat doing calculations,” said Simonsen. “I didn’t realize how much creativity and collaboration is involved in engineering. There is way more complexity than I had ever realized.”

A new path: Shortly after that internship, Simonsen got connected with ExxonMobil through the University of Texas—and she hasn’t looked back since.

- Today, she’s a technical supervisor at the largest polyethylene site in the world, leading teams of engineers, chemists and technicians who perform experimental commercial-scale trials and improvement projects on the tough synthetic resin used in bags, containers and other packaging.

A sense of purpose: Simonsen is particularly interested in opportunities to support sustainability and sees manufacturing as the perfect place to make an impact.

- “I know young people are really passionate about sustainability, making a difference and having a purpose, and all of those are things you can do in manufacturing, especially at a place like ExxonMobil,” said Simonsen. “We are global, we are integrated and we have the resources and scale to impact an entire industry. That’s the reason I came to work here.”

A push for parity: Simonsen also sees how the lack of women in science, technology, engineering and math feeds into a shortage of women in manufacturing, and she’s eager to see more young women find their way into the field.

- That’s why she leads industry meet-and-greet events on behalf of ExxonMobil at the University of Texas, volunteers at “Introduce a Girl to Engineering Day” events for K-12 students in Austin and Houston and hosts lunch-and-learn sessions with UT’s Society of Women Engineers and the American Institute of Chemical Engineers.

- She also leads ExxonMobil’s SWE conference team, who recruit, share sessions and lead “Invent It Build It” outreach activities through SWE.

- “We do a good job of recruiting candidates who reflect the diversity of the pipeline; my classes in college were 30% women, and that’s translating to the same 30% who make their way into ExxonMobil manufacturing,” said Simonsen. “But that’s not 50%, which is why it’s vital to engage women and minorities to get interested in STEM so we can bring them into classes and then the workforce as they graduate.”

New visibility: Recently, Simonsen was named an Emerging Leader in Manufacturing by the 2024 Women MAKE Awards, a distinction for a select few women under the age of 30 who have achieved rare accomplishments at the start of their careers in manufacturing.

Advice for women: While most workers in the industry are still men, Simonsen encourages women to consider the broad range of opportunities available in manufacturing.

- “I would say, ‘Try it,’” said Simonsen. “Consider trying it, even for a short period like an internship. Because if you step in, and you like it, you can find yourself working on the biggest challenges in the world.”

A Merck Manufacturer Leads the Way

For Alexandra Bryant-Boose, being a mentor matters—because she’s seen firsthand what good mentorship can accomplish.

From a mentor at a homeless shelter where she and her mother lived for a time, to an eighth-grade science teacher who pointed her toward a scholarship at an engineering summer program, she is grateful for all the people who helped guide her in the right direction.

- “There were so many experiences where someone gave me an opportunity,” Bryant-Boose said.

Today, as an automation specialist at Merck Manufacturing Division, part of Merck in Durham, North Carolina, Bryant-Boose is paying that opportunity forward, making sure that others are able to find their passion and achieve their dreams.

Discovering manufacturing: Bryant-Boose graduated from North Carolina State University with a degree in chemical engineering, a concentration in biomolecular engineering and a double minor in microbiology and biotechnology.

- When the COVID-19 pandemic hit, she began looking at careers at Merck, and in her words, just stumbled onto automation. After doing some research, she was hooked.

- “Automation is like playing investigative journalism or being a detective,” said Bryant-Boose. “Sometimes there’s a problem and no one will know what the issue is—and automation is about looking into the nitty-gritty, getting a little dirty and opening up a system to find what the issue is. That way of thinking and working is what makes me enjoy what I do.”

Educating young people: In 2022, Bryant-Boose launched a project designed to spread opportunities in science, technology, engineering and math to young people who might not otherwise be able to learn about those subjects.

- She started small in 2022, with a program at a local middle school. Last summer, in collaboration between the Society of Women Engineers and Durham Parks & Recreation, the project grew into a STEM summer camp with about 30 Merck volunteers.

- “We hosted 90 kids in three locations who all got that face-to-face interaction with Merck employees,” she said. “It was a lot of work to organize, but it was good to pay it forward. I’m giving kids someone to look up to and helping them figure out where they might go.”

Promoting support: Bryant-Boose is also a talent acquisition lead for the League of Employees of African Descent at Merck. The internal group, which offers both mentoring and reverse mentoring—in which younger employees provide advice and knowledge to executive team members—gives her a chance to both advise and be advised.

- “I like being able to give people advice that I wish I had,” said Bryant-Boose. “At the end of the day, it’s good to be around people who can relate to things you’re going through. And I find that LEAD allows me to do that at Merck.”

Gaining recognition: Recently, Bryant-Boose was named an Emerging Leader in manufacturing by the 2024 Women MAKE Awards, a distinction for a select few women under the age of 30 who have achieved unique accomplishments at the start of their careers in manufacturing.

Offering advice: Some of Bryant-Boose’s best advice is to encourage people— especially women—to find their own mentors.

- “I know coming into what’s historically been a male-dominated field can be intimidating,” said Bryant-Boose. “If you’re a woman considering manufacturing, or actively getting into it, find that person who can be your mentor. Claim them. Go to them when you need someone to talk to.”

Go deeper: To see the full list of 2024 Women MAKE Award Honorees and Emerging Leaders, click here. To learn more about the Women MAKE Awards, click here, and to learn more about the MI’s free Women MAKE Mentorship Program, click here or contact the team at [email protected].

Can a Factory Offer Flexible Work Schedules?

Manufacturing operations are meticulously scheduled and dependent on consistent in-person labor—so how can employers in the sector give workers the flexibility that many want?

With competition for workers remaining fierce, it’s a question that the Manufacturing Institute (the NAM’s workforce development and education affiliate) has started to tackle. Now, manufacturers looking into providing flexible options can consult a new MI whitepaper that draws on real companies’ experiences and decision-making processes.

The new reality: Flexibility is a high priority for workers nowadays, as the MI’s own research shows.

- “Nearly 50% of manufacturing employees cite flexibility as a reason they stay with their employer, with 63.5% reporting that they would look for more flexibility in their next role if they were to leave their current company.”

Figuring it out: So how are manufacturers adjusting? According to a working group of 17 companies convened by the MI, many manufacturers have started by surveying their workers and talking through options with them.

- While feedback from current employees is often a prime motivator for companies considering flexible work arrangements, some manufacturers also pursue them to attract a wider pool of prospective workers—including parents of young children, who may put a premium on flexibility.

What’s on offer: As feedback from the working group showed, manufacturers are considering a wide range of creative options. The whitepaper cites several intriguing examples, which should give other manufacturers ideas for their own operations.

- One manufacturer in the group was trying out different shift options, remarking that they’re “exploring 4–9s and 4–10s primarily as well as adding a Sunday second shift and having folks on rotating shifts.”

- Other companies organized teams of “floaters.” At one firm, these employees work limited hours on different shifts and acquire a large variety of skills. While not full-time, such positions offer a viable option for workers in search of considerable flexibility.

- Shift swapping was another option under discussion, with one company allowing workers to swap up to a week at a time, so long as a supervisor approved.

How to get started: Check out the full whitepaper for more useful tips, including a toolkit to help companies start making these complex decisions on their own.

- Here is the recommended first step: “Identify the objectives that your company hopes to achieve in providing workplace flexibility by focusing on the challenges that you would like to solve, whether it’s increasing the number of applicants or reducing turnover and absenteeism. Establish your baseline by evaluating your company’s status on these metrics.”

The last word: As one working group participant said, “At our company, we’ve seen what workplace flexibility means for our production workers. The change in company culture is so valuable.”

How Pioneer Service Solves the Retention Puzzle

For Pioneer Service President and Co-Owner Aneesa Muthana, having an engaged team is the key to solving the workforce retention puzzle. The Addison, Illinois–based, woman-owned company is among the many manufacturers that find retention, along with recruitment, to be top business challenges, as the NAM’s Manufacturers’ Outlook Survey shows. So how has Muthana gone about building such a team?

Where it all starts: For Muthana, meeting this challenge begins with upholding the company’s core values: integrity, diversity, leadership, outreach, stewardship, quality and learning.

- These words appear on the shop floor, and every job candidate who comes in for an interview receives a handout outlining their importance. “These are more than just pretty words on a wall,” said Muthana. “We chose these values as a team because they pinpoint our path to success, both financially and ethically.”

- “I give them a copy because I want them to understand the importance from the beginning,” said Muthana. “We want to plant the seed before they’re on our payroll that these are the expectations. Then it becomes fair to hold people accountable to them.”

Providing training opportunities: In keeping with its core values of stewardship and learning, Pioneer Service offers internal training opportunities for employees who express an interest.

- “We offer training to anyone who raises their hand, whether it be in safety or leadership,” said Muthana. “It can also be very technical training on the shop floor. We also provide GD&T training, including for our sales team.”

- GD&T, or geometric dimensioning and tolerancing, determines how parts fit together into an assembly to form a product.

- The benefit of having a salesperson learn about GD&T? “A salesperson would be able to look at a customer print confidently and feel comfortable talking to the customer without needing to have an engineer in the room,” Muthana pointed out.

Offering support: Pioneer Service established a chaplaincy program, which connects employees and their families undergoing hardships—such as caring for an elderly parent, grieving the loss of a loved one or dealing with a personal struggle—with a chaplain who can provide counseling and offer spiritual and emotional support. Muthana says that the chaplaincy program is open to any employee, regardless of religious background or preference.

- “The chaplain service is part of our team,” said Muthana. “We have one chaplain come in every week—one week a male and then the following week a female—who is available to meet with staff if needed.”

- Muthana says she used the service a few years ago when her son, who is in the military, came back from Afghanistan. Many of his friends did not.

- “As a parent, you feel grateful that your child survived, but also guilty for feeling that way because a lot of his friends didn’t come home. The chaplain service provided me someone to talk to because I couldn’t talk to my family, and I couldn’t talk to my staff,” she recalls. “I developed a strong relationship with the chaplain that I feel never would have happened if I didn’t look out for my staff and implemented the service.”

Job shadowing: When Muthana goes to a speaking event or conference, she sometimes takes one or two of her staff with her so they’re able to benefit from attending. It’s also a way for her to get to know her staff on a more personal level, outside of the formal workplace setting.

The last word: Muthana shared some advice for companies struggling with workforce retention:

- “Having an engaged team and workers only happens with a people-first mentality,” said Muthana. “When you take care of them, you become successful because you have an engaged team that has your back.”

- “It’s harder to make a profit than ever. The only way that we’re going to be successful is by having an engaged team.”

Go deeper: The Manufacturing Institute (the NAM’s workforce development and education affiliate) has many resources to help employers retain and develop their teams.

- Start with this study to learn how to build positive company culture and engage employees, explore strategies in boosting retention and employee engagement, delve into tips on attracting and retaining talent in rural vs. urban settings and check out the MI’s recent white paper on flexibility approaches for manufacturing production workers, a key tool to improving the employee experience.

- Pioneer Service’s approach to workplace needs exemplifies the benefits of focusing on the holistic frontline employee experience, which include higher retention, less absenteeism and greater engagement, according to a study conducted by the MI and PwC.

- Learn more about Women MAKE America and the 35×30 campaign, the MI’s initiatives to increase the number of women in manufacturing, tapping into this population to address persistent workforce shortages. Military-affiliated talent and second chance populations are great sources, too.

Three Sisters Build Manufacturing Careers Together

For three sisters in Kentucky, manufacturing is a family affair.

Emily Bastin, Heather Craven and Hannah Geneve are all working in maintenance roles supporting various shops at Toyota Motor Manufacturing Kentucky. Growing up, they had disparate interests—while Emily had taken robotics classes in middle school and Heather had always enjoyed working with her hands, Hannah switched to manufacturing only after working in customer service. Today, all three of them are building careers in manufacturing together.

How they got here: Emily, Heather and Hannah found their way into manufacturing through FAME—an initiative for current and aspiring manufacturing workers that was founded by Toyota in 2010 and is operated today by the Manufacturing Institute, the NAM’s workforce development and education affiliate.

- The FAME Advanced Manufacturing Technician program offers on-the-job training and classroom education that combine technical training with professional practices and lean learnings to create world-class technicians. The two-year AMT program leads to an associate degree and the FAME certificate.

- “They came to my school—the AMT program—and I was like, you know, let’s give this a shot,” said Emily. “I didn’t realize I would have that kind of potential. This was cool stuff.”

The family business: Emily was the first of the three sisters to graduate from FAME, and she has been helping her sisters as they work their way through the program. Both Hannah and Heather are enrolled in FAME while working at Toyota, and they expect to graduate in May 2025.

- “We’re all working in the same plant, and if they need anything from me, I’m there to be supportive,” said Emily.

- “With schoolwork, I try to help Heather, and she tries to help me,” said Hannah. “We all help where we can.”

- “It’s nice to have that sister love to lean on,” said Heather. “They understand the frustration of school and work, and it’s been a pleasure to work with them.”

Opportunities abound: The sisters advise others who might not have considered manufacturing as a career—especially women—to give the industry a second look, emphasizing the sheer diversity of jobs on offer.

- “Working in manufacturing doesn’t necessarily mean you’re working on a factory floor,” said Hannah. “There’s an administrative side, an HR side—there’s a lot more to manufacturing than people expect.”

- “I do see us being examples for women who might not normally see themselves in the field,” said Heather. “You want to see women come in and say, hey, I did it, and you can, too. It’s nice to see yourself reflected back.”

The community: It’s not just their family ties that keep the sisters in manufacturing. All three sisters have high praise for their fellow students and colleagues, and for the supportive culture they’ve encountered at Toyota.

- “The mentorship I got helped me gain my confidence while I was learning,” said Emily. “And even now, the teamwork that goes into everything, every day—it’s been a nice surprise.”

- “Everyone has been super nice, super helpful and super welcoming,” said Hannah. “When you start out, it can seem intimidating, but everyone’s willing to help you out. They really want you to succeed.”

The last word: “It’s nice to feel like you’re a part of that network—that family,” said Heather.

The MI’s 35×30 campaign aims to increase the share of women in manufacturing to 35% by 2030 and spotlights outstanding women in the industry like these sisters. To learn more about Women MAKE America and explore its many opportunities, including its new mentorship program, go here.

The Federation for Advanced Manufacturing Education provides global-best workforce development through strong technical training, integration of manufacturing core competencies, intensive professional practices and intentional hands-on experience to build the future of the modern manufacturing industry. Learn more here.